Reference Price:

Get Latest Price

Production Capacity:200-10000t/d

Main equipment: crusher machine, raw material mill, cement ball mill, cement rotary kiln, etc

We are the cement plant manufacturer with 30 Yrs history in China and we will provide professional solutions at factory price for you.

Email:sales@zdzg.com (contact us by one of the three ways)

Email: sales@zdzg.com (contact us by one of the three ways)

Zhongde Heavy Industries Co., Ltd. China(Mainland)

Response Time <24h

Factory Price 100%

Online Service 24h

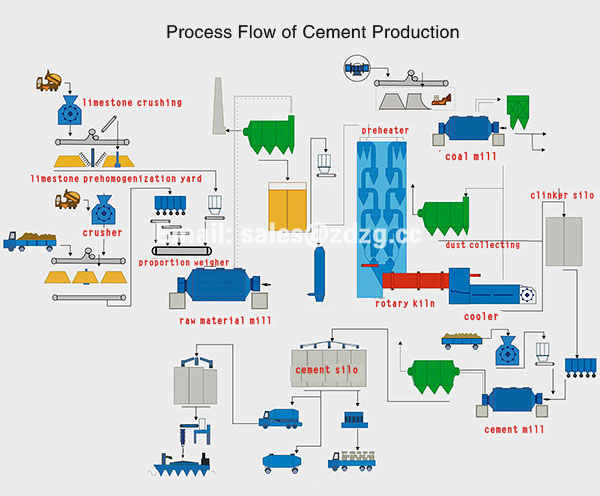

Generally,cement production line mainly consists of the following steps:raw material crushing-raw material grinding-preheating-cement calcination-cooling-clinker grinding-cement packing.

The main equipment in cement production line includes crusher machine, raw material mill, cement ball mill,cement rotary kiln,cooling system and packing machine and so on.

1.Crushing and Preblending

In cement production plant,raw material crushing and preblending is the first step.Limestone is the main raw material for cement making and it needs to be crushed by jaw crusher or impact crusher. Bauxite is the additive.They need to be crushed firstly.

2.Raw Material Grinding

In cement production, it needs to grind tons of materials (including raw materials, fuel, clinker, mixed materials,etc). The bauxite particles and limestone particles are grinded into raw powder by raw mill,realizing material preblending.

3.Preheating System

Preheating procedure is the important step before cement calcinetion.

4.Cement Calcination in Rotary Kiln and Cooling

The calcination is a key step of cement production ,it makes directly influence on the quality of cement clinker.Rotary kiln is the most widely used cement calcination plant. After calcination,cooling process is to make the clinker reach required temperature.

5.Clinker Grinding in Cement Ball Mill

Cement ball mill is used for grinding cement clinker to the appropriate size,optimizing cement particle grade.Cement ball mill plays an important role in this procedure.

6.Packing and Transportation

After all the necessary steps,packing and final product transportation is the last procedure.

1. Large Production capacity, it is 200t/d~10000t/d.

2. Provide full set of dry cement process plant with CE&ISO quality certification at factory price.

3.On-site guifance,free tech-service support,product installation,full after-sales service.

4.Professional project design,customized solution available.