Reference Price:

Get Latest Price

Production Capacity

150-1000t/d

Production capacity 12-1000 t/h

Max Input Size 35-300mm

Discharging Range 3-60mm

Processing Materials: gypsum,lime,bauxite,spong iron,bentonite, etc

Email:sales@zdzg.com (contact us by one of the three ways)

Email: sales@zdzg.com (contact us by one of the three ways)

Zhongde Heavy Industries Co., Ltd. China(Mainland)

Response Time <24h

Factory Price 100%

Online Service 24h

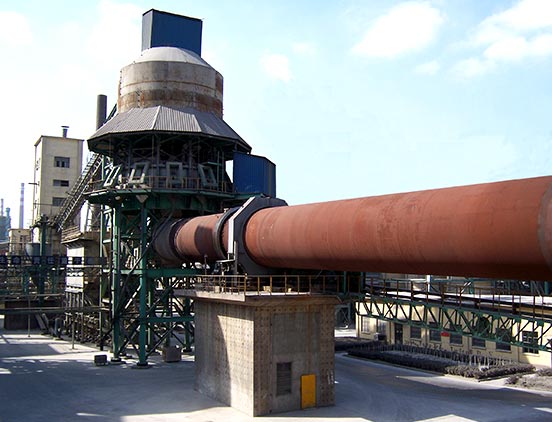

Introduction of Rotary Kiln

1.Rotary kiln is the commonly used calcination plant.Generally,rotary kiln can be divided into cement rotary kiln and metallurgy & chemical kiln according to the difference of processing materials.

2.Cement rotary kiln is used for cement clinker calcination, it is the important equipment in cement production line.Metallurgy & chemical kiln can be used to process lime,gypsum,bauxite,bentonite,spong iron,coke and other materials.

3.Rotary kiln is mainly composed of kiln body,rotating device,riding wheel,sealing device and other parts.

4.Compared with other kinds of kiln,rotary kiln has more uniform and evenly calcination effect due to its continous movement of kiln body.

5.Rotary kiln has full models and large processing capacity,you can choose the proper model according to your needs and requirements.

Advantages of rotary kiln

1.Reliable performance,stable operation

2.Advanced sealing device,uniform and even calcination effect

3.Professional design,reasonable structure

3.Energy saving,easy maintenance

4.Various kinds of fuels are available

5.Reasonable process,compact layout,high automation level

| Product Specification (m) |

Kiln dimensions | Motor power (kw) |

Total weight (t) |

note | ||||

| Diameter (m) |

Length (m) |

Obliquity (%) |

Capacity (t/d) |

Rotation speed (r/min) |

||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 | ----- |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ----- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | outside disassemble kiln |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | outside disassemble kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | outside disassemble klin |

| Φ3.0×60 | 3 | 60 | 3.5 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | disassemble klin |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | kiln with preheater precalcine |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | kiln with prehrater precalcine |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Generating klin for usimg oZDerheat |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | klin with prehrater precalcine |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | klin with prehrater precalcine |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 | klin with prehrater precalcine |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | klin with prehrater precalcine |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | klin with prehrater precalcine |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | klin with prehrater precalcine |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | klin with prehrater precalcine |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | klin with prehrater precalcine |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | klin with prehrater precalcine |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | klin with prehrater precalcine |